In-line Leak Detection

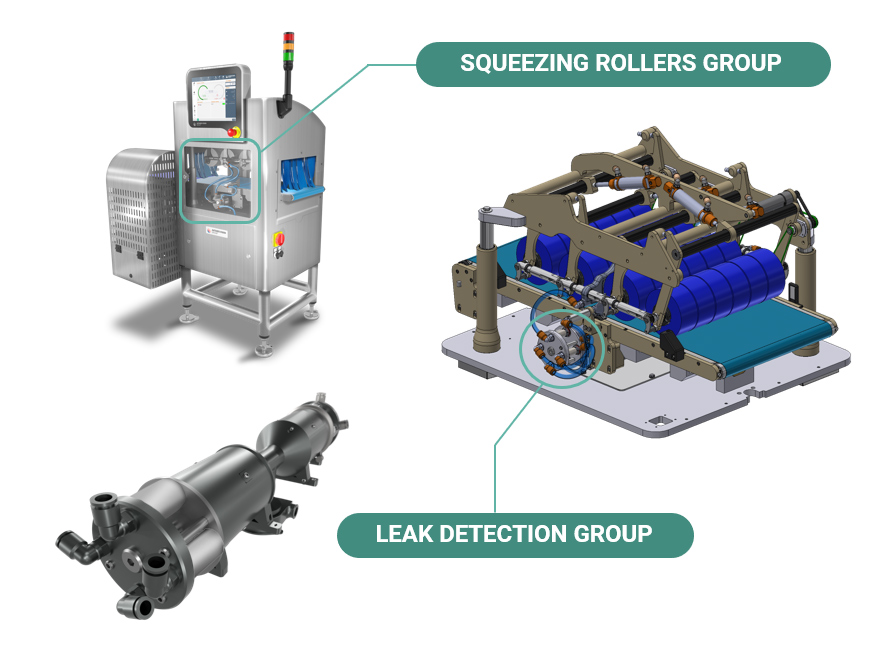

MACHINE OVERVIEW

LDS (Leak Detection System) is a solution by Antares Vision Group that performs non-destructive checks on 100% of production, guaranteeing food safety and quality of the final product. The inspection system uses IR spectroscopy technology (gas sensors) that detects, if there are holes or micro-holes on the packaging and/or seal, any CO2 leaking from the package.

Here we can see the latest version of LDS, which has been subject to a complete re-engineering process by AV Electronics.

The process that led this release started with the following analysis points:

- Would it be possible to reduce the length of the pipes?

- Would it be possible to reduce the distance between sniffing points and pump?

- Would it be possible to reduce the number of electronic boards?

- Would it be possible to simplify wiring process and save assembly time?

- Would it be possible to speed up maintenance operations?

The systemic approach highlights that it is not possible to further improve the system by remaining tied to electromechanical standard components.

But the introduction of highly integrated and customized components would bring important advantages regarding all the aforementioned points.

In the first place, it would make it possible to re-think the system, optimizing many aspects.

AV Electronics started by redesigning the inspection module, moving it from above the squeezing rollers group to below the conveyor belts;

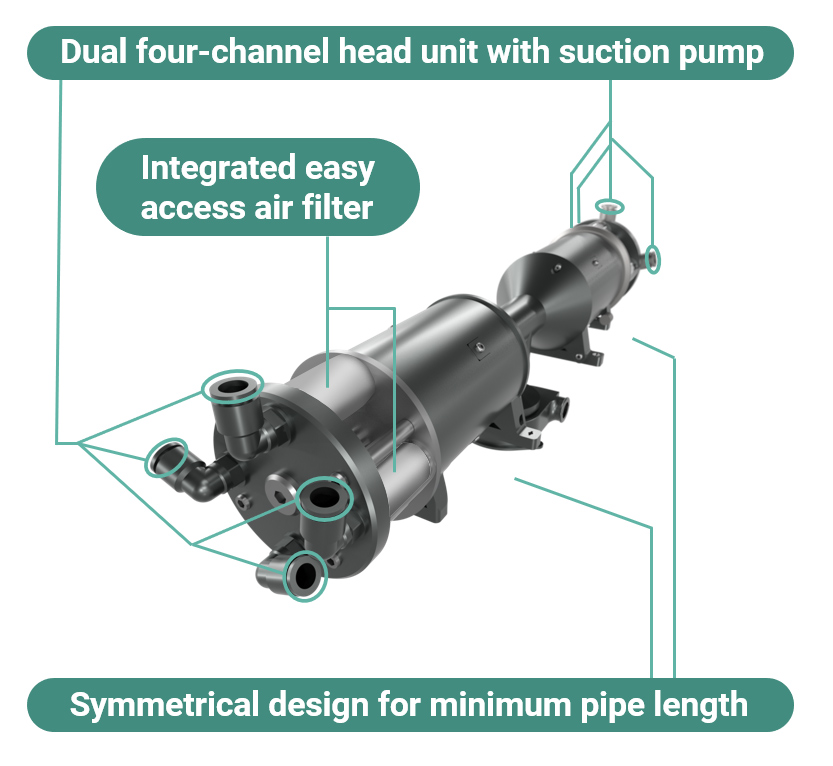

NEW CUSTOMIZED INTEGRATED UNIT:

COMPLETE CO2 SENSOR ASSEMBLY

Together with its symmetrical design, this shift allows you to get closer to the 8 sniffing points, reducing the path of the pipes and the distance between sniffing points and suction pump.

The air filters are left exposed to facilitate maintenance operations.

The component is completed by an adjustable chopper speed and the possibility of obtaining significant energy savings in stand-by mode.

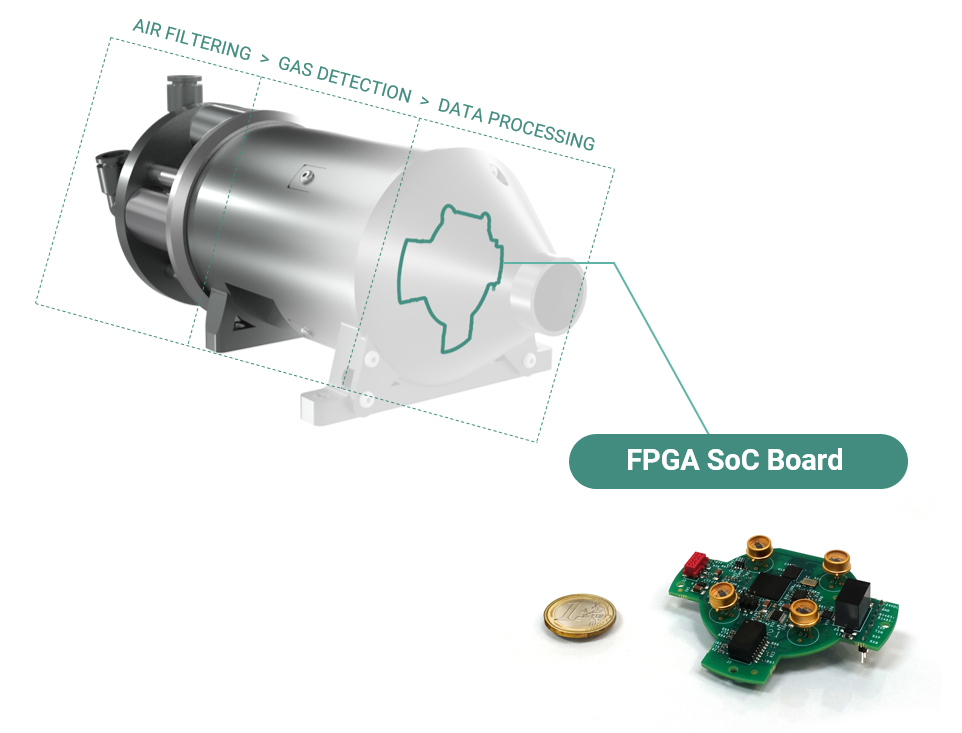

NEW INTEGRATED UNIT:

INTERNAL VIEW

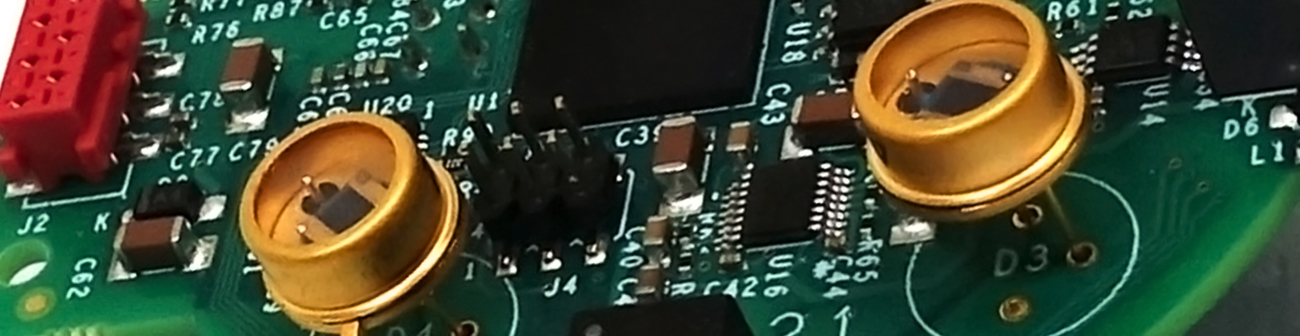

Inside the unit we can see the real innovation: CUSTOMIZED ELECTRONIC COMPONENTS, optimized for the real need of the system.

A closed and compact module that integrates in a few centimetres 3 functions that in the previous version were located in different positions: filtering, gas detection and data processing via the electronic board.

A tiny electronic board, which alone performs all the necessary functions previously performed by different cables, connectors, etc.

An innovative, effective, efficient and cost-saving solution.

BENEFITS

- SPACE for pipes and boards reduced by 50%

- COST for components reduced by 20%

- TIME for assembly reduced by 50%

- EFFICIENCY improvement across entire SUPPLY CHAIN

- DISTINCTIVE and ADVANCED technological solution